If you’ve paid attention to EVs, smartphone fast chargers, or solar power systems, you might notice these devices are getting smaller and more efficient. Behind this lies an “unsung hero” — the thin copper strips inside transformers. Let’s break down why these strips are game-changers and why giants like Tesla and Huawei are adopting them!

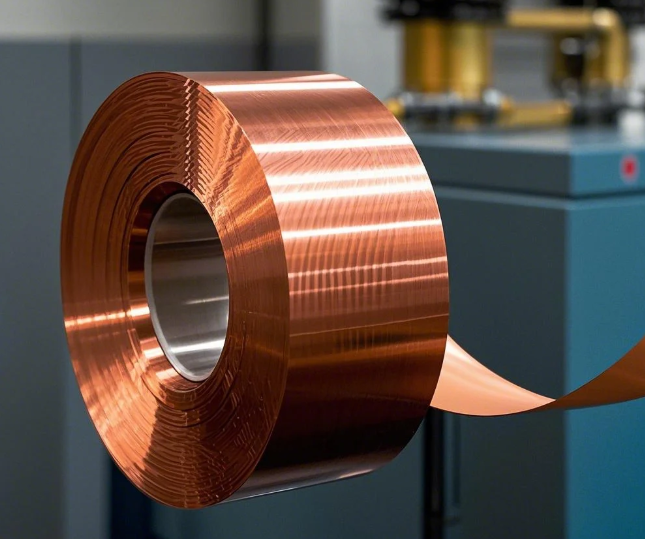

What Are Transformer Thin Copper Strips?

Think of them as “flattened copper wires” — as thin as half a human hair (0.05–0.5mm) but several centimeters wide, resembling ultra-thin metallic tape. This design lets them outperform traditional round copper wires in high-frequency, compact devices.

Where Are They Used? — 4 Hot Applications

- 1.Smartphone Fast Chargers

- There was a time that chargers were brick-sized; now they’re thin as credit-card ! The secret? Mini transformers using thin copper strips. Example: Huawei Mate 60s 100W charger is just 1.5cm thick.

- 2.EV Charging Station

- Tesla’s V4 Supercharger uses 0.2mm copper strips to hit 350kW charging (100km range in 5 minutes) while shrinking the unit size by 50%

- 3.Rooftop Solar Power Systems

- Solar inverters with copper strip-based transformers boost efficiency from 97% to 99% — earning 3% more electricity yearly (hundreds of dollars in savings)

- 4.Foldable Phone Wireless Chargers

- Samsung Galaxy Z Fold 7’s wireless charging module uses 0.08mm copper strips, surviving 5,000 bends without damage, and is only 2mm thick.

5 Advantages of Thin Copper Strips

- 1.Energy Saving: No Overheating at High Frequencies

- Traditional copper wires act like “traffic jams” at high frequencies, forcing current to crowd the surface (called the “skin effect”). Thin copper strips widen the “road” into a “flat highway,” letting current flow smoothly. Tests show 40% less energy loss at 500kHz

- 2.Space-Saving Magic

- Copper wires leave gaps like tangled yarn, while thin strips stack tightly like folded paper, achieving 95% space efficiency. A transformer with copper strips can be 30% smaller — imagine an EV charger fitting into your car trunk!

- 3.Longer Life-span

- The wide surface of copper strips dissipates heat better, running 15–20°C cooler than wires. Example: Solar inverters in scorching sunlight last 15 years instead of 10.

- 4.Cost-Effective & Eco-Friendly

- Less material waste, easier recycling (no chemical stripping needed), and 8–12% lower total cost. For a factory making 100,000 transformers yearly, this saves millions.

- 5.Future-Proof Tech

- 6G Networks: MHz-level transformers demand ultra-thin strips

- Wearables: Flexible strips can bend endlessly, ideal for smartwatch coils.

What Do Users Actually Experience?

1.Faster Charging: Phones charge in 30 minutes; EVs refuel like gas cars.

2.Lighter Gadget: Laptop chargers shrink from “bricks” to “cards”.

3.Lower Bills: Home solar systems earn 3% more yearly.

How Are Industry Leaders Using Them?

TESlA: Built its own 0.1mm copper strip production line to cut Supercharger costs by 20%.

CATL:Invested $10B in copper strip factories for 800V EV battery systems.

XIAOMI:World’s thinnest 0.05mm strips power its foldable phone wireless charging.

From pocket-sized chargers to space stations, thin copper strips are rewriting the rules of power devices. Next time you charge your phone in minutes or slip a charger into your wallet, remember — there’s a layer of “tech magic” inside.